Reverse Engineering

Reverse engineering is the process of deconstructing and analyzing existing structures, systems, or components to recreate, improve, or adapt them for new purposes. This service is essential for upgrading outdated systems, troubleshooting design flaws, and optimizing performance. Our reverse engineering solutions provide precise, actionable insights to help clients enhance their operations and achieve superior results.

Why Choose Our Reverse Engineering?

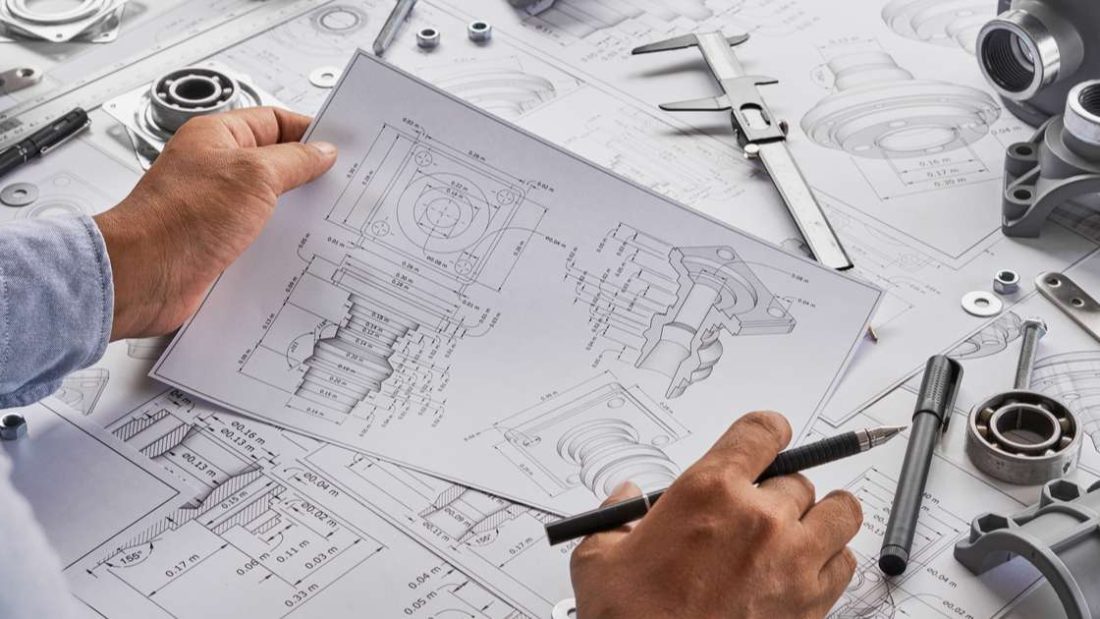

We utilize advanced tools such as:

- 3D Scanners: To create accurate digital models of physical objects.

- Finite Element Analysis (FEA): To simulate stress and performance.

- CAD Integration: Ensuring smooth transitions from analysis to prototyping.

This ensures unparalleled accuracy and efficiency in our reverse engineering process.

Our team includes:

- Experienced engineers skilled in mechanical, structural, and materials engineering.

- Drafting professionals adept at creating precise technical documentation.

- Analysts proficient in computational simulations and load evaluations.

We bring together diverse expertise to tackle even the most complex projects.

Reverse engineering helps businesses save costs by:

- Extending the lifespan of existing systems instead of investing in new ones.

- Enhancing efficiency to reduce operational expenses.

- Offering customized solutions that fit within your budget constraints.

Our streamlined processes and advanced tools allow us to:

- Quickly capture and analyze existing systems.

- Deliver accurate designs in a fraction of the time traditional methods take.

- Expedite project completion without compromising on quality.

- We adapt our services to meet the unique requirements of each client.

- Our designs can incorporate modern upgrades, advanced materials, or entirely new functionalities.

- We cater to a wide range of industries, ensuring relevance and applicability.

By rigorously analyzing loads, materials, and performance, we ensure that every reverse-engineered component meets the highest safety standards. This reduces the risk of failures and improves long-term reliability.

We provide end-to-end assistance, including:

- Initial surveys and data collection.

- Technical documentation and drafting.

- Implementation and testing of redesigned systems.

- Ongoing support for further enhancements or maintenance.